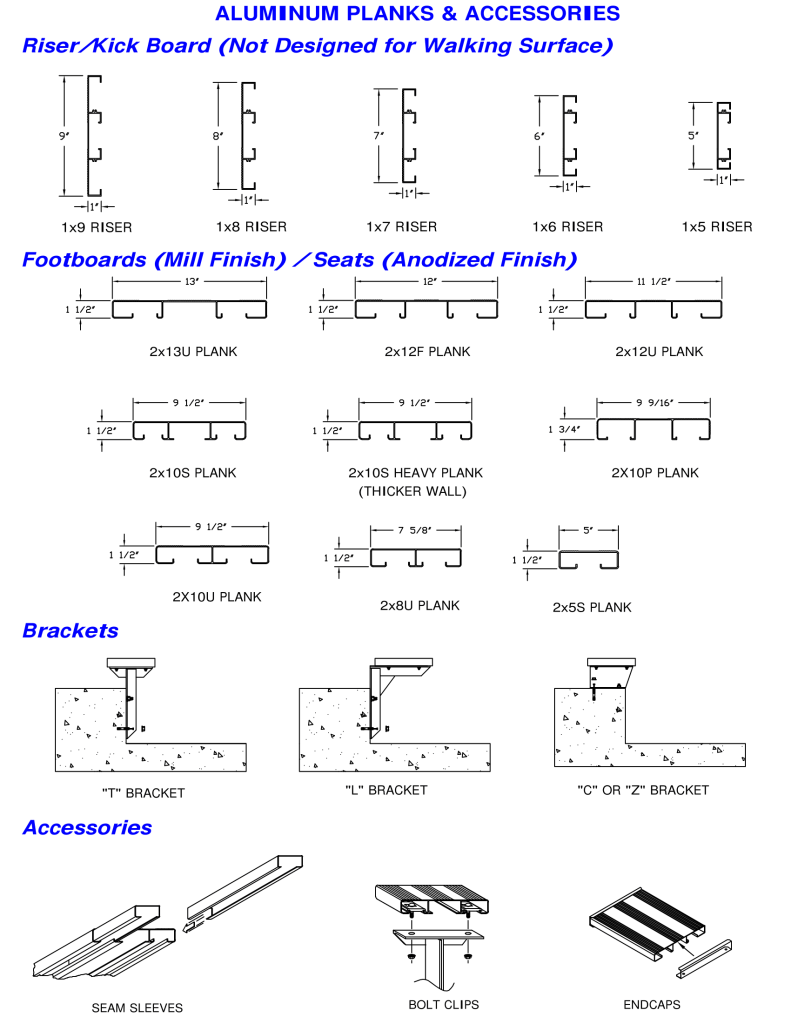

Aluminum Bleacher Planks & Repair Accessories

In addition to selling full bleacher and bench units, we also sale individual lengths of aluminum bleacher planking, attachment hardware, and attachment framing components.

American Aluminum Seating Inc. offers a wide range of different aluminum extrusion dimensions in a variety of finishes, including the standard mill finish, anodized, and powder coated options.

Aluminum bleacher planking can be used in several applications outside of bleachers, benches, and picnic tables. Aluminum planks make a durable surface for trailers, performance stages, and a longer lasting lasting alternative to wood in many other applications.

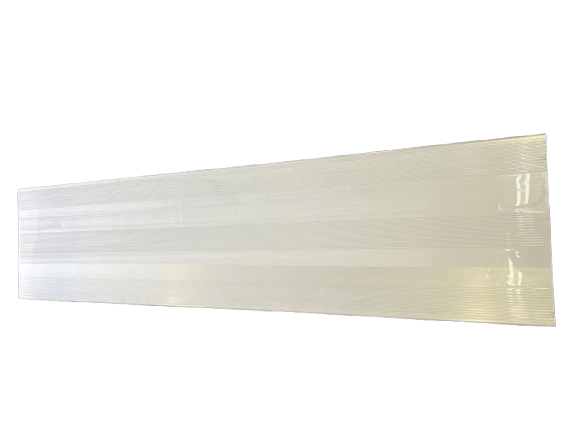

Aluminum Brightener

When purchasing your aluminum planks, consider adding aluminum cleaner and brightener to your purchase. Despite aluminum’s low maintenance and durability, over the years, aluminum can become dirty and stand out against newer replacement planks.

This aluminum cleaner may also be used for water stained plank in the event staining occurs from improperly stored mill finish plank that gets wet.

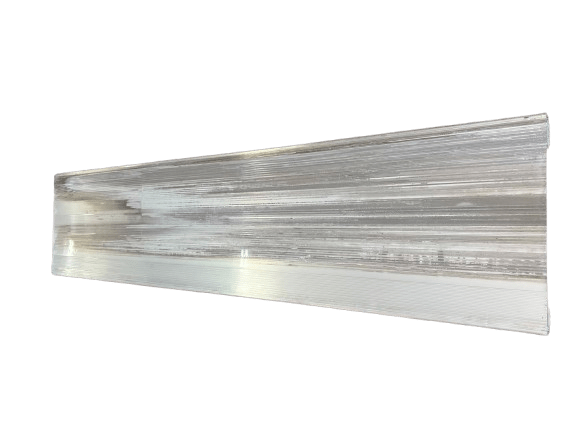

BEFORE

AFTER

Mill Finish Aluminum Stains/ Discoloration

American Aluminum Seating, Inc. designs, fabricates bleachers in the Unites States and overseas. Aluminum extrusions are used for seats, riser boards and foot boards in all of our designs. The seats are usually specified to have an anodized finish, which provides a uniform satin protective film finish on the aluminum. The foot boards and riser are usually specified and provided with a mill finish, which is shinny when new and will dull with age and usage. This practice has been prevalent since aluminum extrusion were first introduced over 40 years ago.

Ours customers usually purchase mill finish because it is less expensive than anodized finish and it provides the customer the most economical product. Use of mill finish aluminum results in water stains and discoloration of some or all the products. Aisle, walkways and ramps where mill finish are used are heavy traffic areas on the bleacher. They are subject to foot traffic, mud, spilled beverages and food in addition to any water stains and discoloration encountered during construction. Over time the foot boards used in these areas will darken and stain under weather and normal usage because they are not anodized. The used look and blend in color and stains are and have been standard industry practice for many years.

The Aluminum Association of America literature provides a detailed explanation of the cause and result of water staining of mill finish aluminum. Important facts are:

- They are caused by entrapment of moisture between adjacent surfaces of closely packed materials in transit or in storage at the job site during construction.

- Water Stains are superficial and do not cause any change to the mechanical and structural properties of the metal.

- Condensation is the most probable cause of water stains and cannot be avoided during the transportation and material storage on an outdoor construction site.

American Aluminum Seating, Inc. considers that the stained/discolored mill finish foot boards are normal and cost effective part of our bleacher design that meets all requirements in our standards specifications.

Customers who want a more uniform protected appearance with better resistance to stain have an option to order the riser to be anodized finish at an additional cost. American Aluminum Seating, Inc will not anodize footboards as they will become very slippery while walking on. Please contact your distributors that are representing American Aluminum Seating, Inc. regarding this option.

Note: If you choose to use mill finish footboards, expect that water stained boards will be installed.